Superalloy InconelX-750/ UNS N07750/ AlloyX-750 Umbhobho ongenamthungo, Ishiti, ucingo

Iimveliso ezifumanekayo

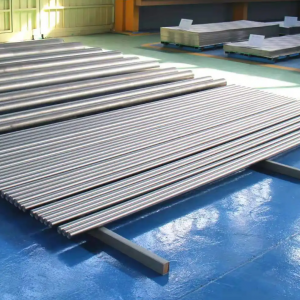

ityhubhu engenamthungo, iPlate, intonga, iiForgings, iFasteners, iFittings yePipe

Imigangatho yeMveliso

| Imveliso | I-ASTM |

| Imivalo kunye neForgings | B 637 |

Ukuqulunqwa kwemichiza

| % | Ni | Cr | Fe | C | Mn | Si | S | Ti | Nb+Ta | Al | Co | Cu |

| Min | 70.0

| 14.0 | 5.0 |

|

|

|

| 2.25 | 0.70 | 0.40 |

|

|

| Max | 17.0 | 9.0 | 0.08 | 1.00 | 0.50 | 0.010 | 2.75 | 1.20 | 1.00 | 1.00 | 0.50 |

Iipropati Zomzimba

| Ukuxinana | 8.28 g/cm3 |

| Ukunyibilika | 1393-1427℃ |

Iimpawu ze-Inconel X-750

I-Inconel X-750 ingxubevange ikakhulu yi-nickel-based superalloy eyomelezwe ngeminyaka nge-γ[Ni3(Al, Ti, Nb)] isigaba.Inokumelana ne-corrosion elungileyo kunye nokumelana ne-oxidation ngaphantsi kwe-980 ℃, kwaye ngaphantsi kwe-800 ℃ inokumelana nokunyuka okuphezulu.Inobuxhakaxhaka bokuphumla obuhle obungaphantsi kwe-540 ° C, kunye nokubunjwa okulungileyo kunye ne-weldability.Le ngxubevange isetyenziselwa ukwenziwa kweenjini zenqwelomoya ezisebenza ngaphantsi kwama-800°C kwaye zifuna amandla aphezulu..Imithombo ingasetyenziselwa ukwenza iiblade zeinjini yeinjini yomphunga kunye nezinye iindawo, ezinje ngeepleyiti, imicu, imivalo, iingcingo, imisesane, iingcingo, imibhobho, njl.

I-Inconel X-750 Inkqubo yoNyango lobushushu

Inkqubo yokulungiswa kobushushu besisombululo kwiipleyiti, imicu kunye nemibhobho kwindawo yokubonelela yi-980 ℃ ± 15 ℃, ukupholisa umoya.Kwinkqubo yonyango yokushisa ephakathi kwezinto kunye neengxenye, ezi nkqubo zilandelayo zingakhethwa kunyango lokushisa.

I-Anealing: 955~1010℃, ukupholisa amanzi.

Ukufakwa kweendawo ezidityanisiweyo phambi kwe-welding: 980℃, 1h.

Ukuthomalalisa kuxinzelelo lwamalungu adityanisiweyo: 900℃, ukufuma kangange 2h.

Ukuphelisa uxinzelelo: 885℃±15℃, 24h, ukupholisa umoya.

I-Inconel X-750 Iindidi ezifumanekayo kunye neNgcaciso

Imivalo, i-forgings, imisesane, amashiti ashushu, amashiti aqengqelekayo abandayo, imicu, iityhubhu kunye neengcingo zinokubonelelwa ngobukhulu obahlukeneyo.

Iipleyiti kunye nemicu zibonelelwa ngokubanzi emva eshushu okanye kubanda rolling, annealing okanye isisombululo, pickling kunye nokupolisha.

Imivalo, i-forgings kunye neendandatho zinokubonelelwa kwi-forged okanye i-hot rolled state;banokubonelelwa ngonyango lwesisombululo emva kokwenza;imivalo inokubonelelwa emva kwesisombululo kwaye ipolishwe okanye ijikwe, kwaye inokubonelelwa ngokubanda xa iodolo ifuna ukuTsala indawo kwindawo.

Ucingo lunokunikezelwa kwimeko yesisombululo esiqinileyo;ngocingo olunobubanzi obuncinci okanye ubukhulu obungaphantsi kwe-6.35mm, lunokuba sisisombululo esiqinileyo kwaye sinikezelwe nge-deformation yomzobo obandayo we-50% ukuya kwi-65%;idiameter yegama okanye ubude becala bukhulu kune-6.35mm.Ucingo, emva kokunyangwa kwesisombululo, lunikezelwa nge-deformation ebandayo yokuzoba engekho ngaphantsi kwe-30%.Kwiingcingo ezinobubanzi obuqhelekileyo okanye ubude becala obungekho ngaphezu kwe-0.65mm, banokubonelelwa nge-deformation ebandayo yokuzoba engekho ngaphantsi kwe-15% emva konyango lwesisombululo njengoko kufuneka.

Inconel X-750 Iindawo zokuSebenza

I-alloy isetyenziselwa kakhulu ukuveliswa kwemithombo yamagqabi kunye nemithombo ye-coil eneemfuno zamandla aphezulu kunye nokumelana nokuphumla kwii-aero-injini ezisebenza ngaphantsi kwe-800 ° C.Isenokusetyenziswa ukwenza iindawo ezifana neebhleyidi zomoya.Iindidi ezifumanekayo lishiti, umcu, ibha, iforging, iringi, ucingo kunye netyhubhu.