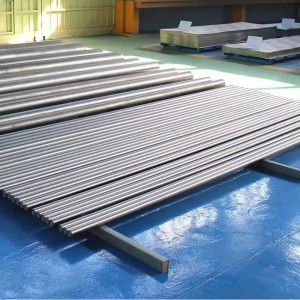

I-HastelloyB-3 / i-UNS N10675 Iityhubhu, ipleyiti, izifakelo, iiForgings, intonga

Iimveliso ezifumanekayo

Ityhubhu engenamthungo, ipleyiti, intonga, iForgings, iFasteners, iStrip, ucingo, izifakelo zemibhobho

Imigangatho yeMveliso

| Iimveliso | I-ASTM |

| Ibha | B 335 |

| Ipleyiti, iphepha kunye nomcu | B 333 |

| Imibhobho engenamthungo kunye nezifakelo | B 366 |

| Umbhobho odityanisiweyo | B 619 |

| Umbhobho odityanisiweyo | B 626 |

| Ukufakwa kombhobho odityanisiweyo | B 366 |

| Iiflange zombhobho owenziweyo okanye oqengqelekisiweyo kunye nokufakwa kombhobho owenziweyo | B 462 |

| Iibhilithi kunye neentonga zokubumba | B 472 |

| Forgings | B 564 |

Ukuqulunqwa kwemichiza

| % | Ni | Cr | Mo | Fe | Ti | Co | C | Mn | Si | P | S | V | Ti | Cu | Nb |

| imiz | Ibhalansi | 1.0 | 27.0 | 1.0 | |||||||||||

| max | 3.0 | 32.0 | 3.0 | 0.2 | 3.0 | 0.01 | 3.0 | 0.1 | 0.030 | 0.010 | 0.2 | 0.2 | 0.2 | 0.2 |

Iipropati Zomzimba

| ukuxinana | 9.22 g/cm3 |

| Ukunyibilika | 1330-1380℃ |

I-Hastelloy B-3 i-alloy ilungu elitsha lentsapho ye-nickel-molybdenum alloys, enokumelana ne-corrosion egqwesileyo kwi-hydrochloric acid nakweyiphi na iqondo lokushisa kunye noxinzelelo.Kwangaxeshanye, ikwanazo nokuxhathisa okulungileyo kwi-asidi ye-sulfuric, i-acetic acid, i-fomic acid, i-asidi ye-phosphoric kunye nezinye i-media ezingezo-oxidizing.Ngaphezu koko, ngenxa yokulungiswa kokwakheka kweekhemikhali, ukuzinza kwayo kwe-thermal kuye kwaphuculwa kakhulu xa kuthelekiswa ne-original Hastelloy B-2 alloy.I-Hastelloy B-3 i-alloy inokumelana nokunyuka kwe-corrosion, uxinzelelo lwe-corrosion cracking, i-knife corrosion kunye ne-corrosion kwindawo echaphazelekayo yokushisa.

I-alloy ye-Hastelloy B-3 yenye i-alloy esekelwe kwi-nickel ehamba phambili emva kwe-alloy ye-B-2.Inokwakheka kweekhemikhali ezilungiselelwe ngokukodwa ukufikelela kwinqanaba eliphezulu lokuzinza kwe-thermal kunezinye i-Hastelloy alloys ezifana ne-B-2 kwaye inokumelana okugqwesileyo kwi-pitting, i-crevice corrosion, i-corrosion yoxinzelelo, i-knife corrosion kunye ne-thermal effects effects ukubola.Ngenxa yozinzo oluphuculweyo lwe-thermal ye-alloy ye-B-3, iingxaki ezifunyenwe ekwenziweni kweengxenye ezifana ne-alloy ye-B-2 ziyancipha ngenxa yokunciphisa imvula yezigaba ezinobungozi eziphakathi kwi-B-3 ye-alloy trend.Oku kubonelela nge-ductility ephezulu kune-B-2 alloys phantsi kweemeko zebhayisikile ezishushu ezifana nokuphosa kunye ne-welding.

Le nickel-molybdenum alloy inokumelana okubalaseleyo kuzo zonke izigxina ze-hydrochloric acid kwindawo ejikeleze amaqondo obushushu aphezulu.Iphinde ixhathise kwi-sulfuric, i-acetic, i-formic kunye ne-phosphoric acids kunye nezinye i-media ezingenayo i-oxidizing.I-B-3 nayo inokumelana okugqwesileyo kwi-pitting kunye noxinzelelo lwe-corrosion cracking.

IiPropati zeMathiriyeli ze-B-3 Alloy

Ukuchasana okugqwesileyo kwi-hydrochloric acid kuzo zonke izigxina kunye namaqondo okushisa, ukuchasana ne-sulfuric, i-acetic, i-fomic kunye ne-phosphoric acids kunye nezinye i-media non-oxidizing Ukuchasana ngokugqwesileyo kwi-pitting kunye noxinzelelo lwe-corrosion cracking.

Ukusetyenziswa okuqhelekileyo kweHastelloy B3

I-alloys ye-Hastelloy B ye-alloys idla ngokusetyenziswa kwiindawo ezinoburharha kunye nezomeleleyo, kwaye zisetyenziswa ngokubanzi kwiikhemikhali, i-petrochemical, amandla kunye nokulawula ungcoliseko, ngakumbi kumashishini afana ne-sulfuric acid, i-hydrochloric acid, i-phosphoric acid, kunye ne-acetic acid, efana ne-distillation. kunye nokuxinwa kwe-hydrochloric acid;uxinzelelo oluphantsi Oxylated acetic acid (HAC);irabha ye-halogenated butyl (HIIR);imathiriyeli ekrwada ye-polyurethane kunye nemveliso ye-alkylation ye-ethylbenzene kunye nezinye izixhobo zenkqubo.

Ngenxa yexabiso eliphezulu, ukusetyenziswa kwe-alloys ye-Hastelloy B yochungechunge igxininisekile, ngokukodwa kwimveliso ye-acetic acid (i-oxo synthesis) kunye neenkqubo ezithile zokubuyisela i-asidi ye-sulfuric, ezifana ne-evaporators kunye ne-dilute iitanki zokugcina i-sulfuric acid kubunjineli be-acetic acid.